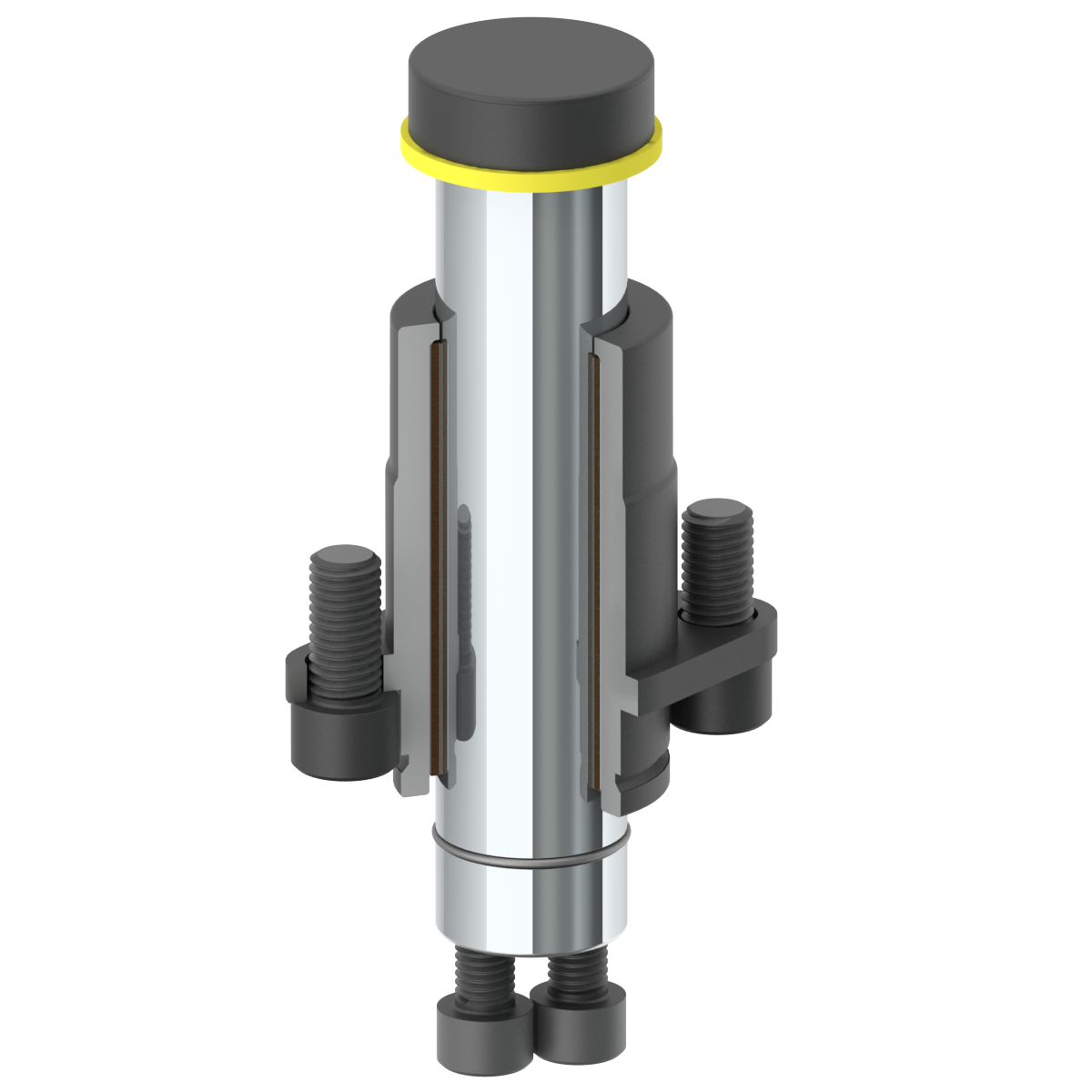

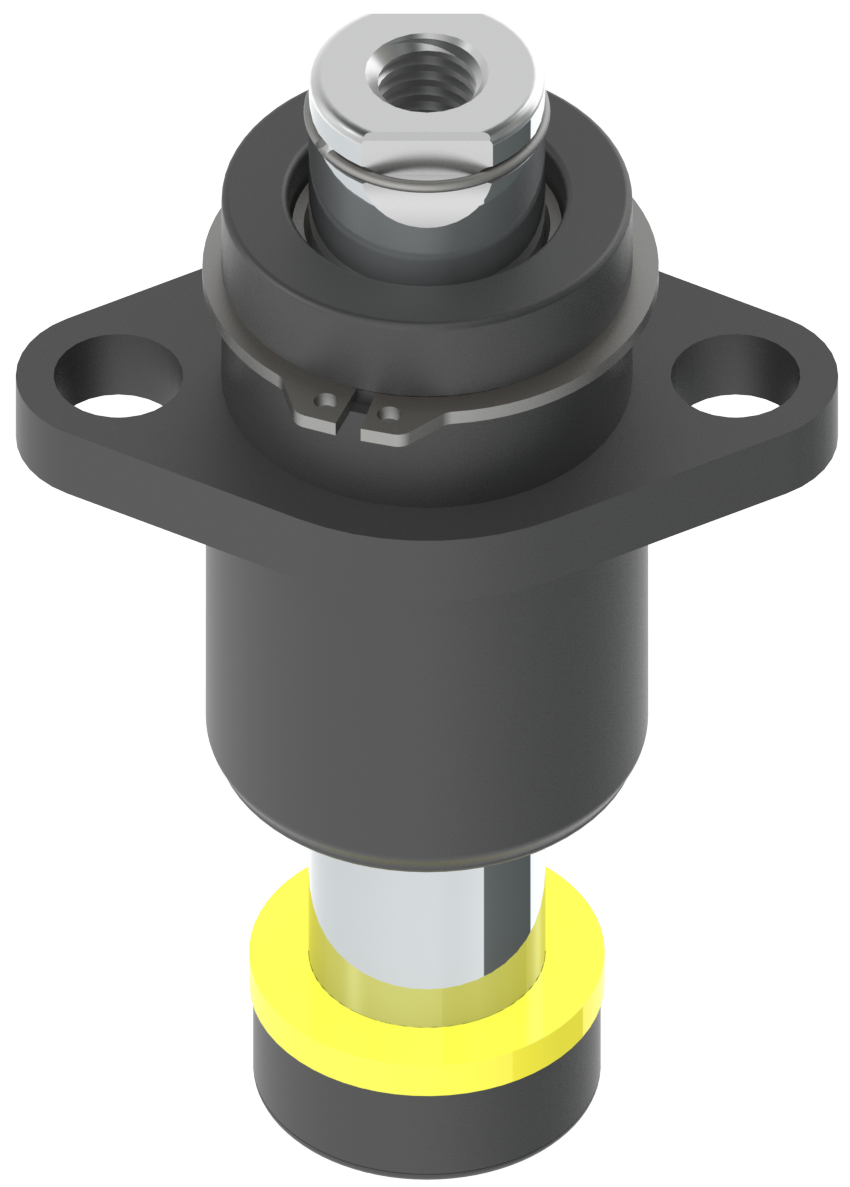

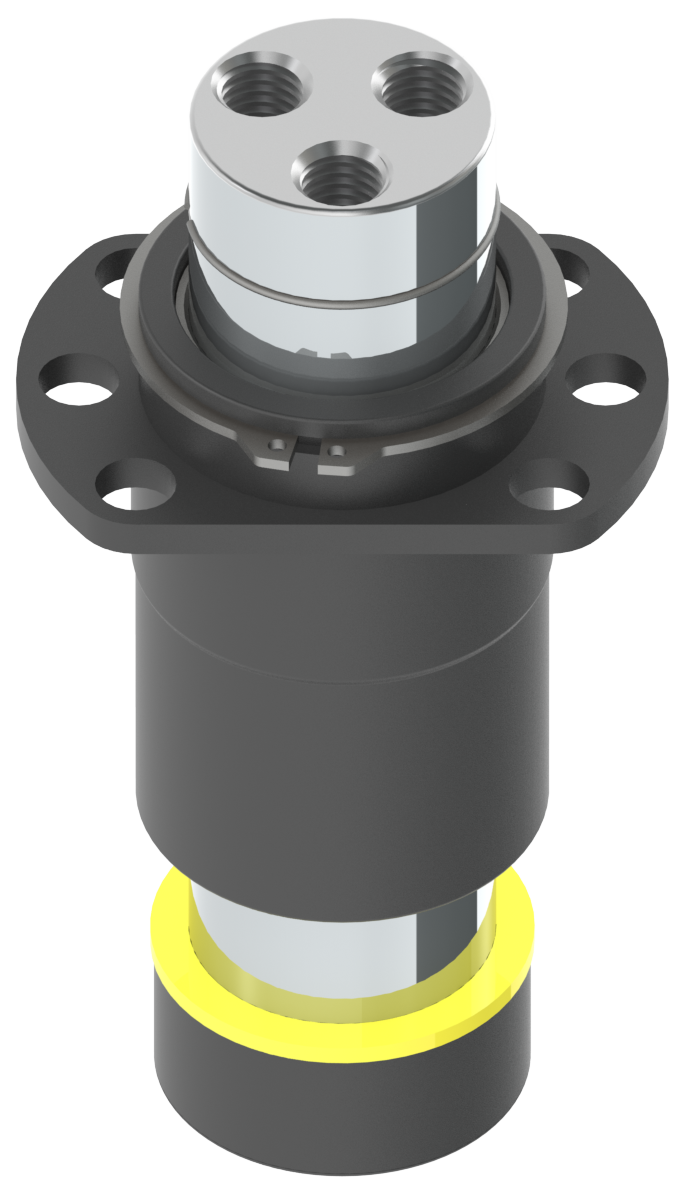

Guidance and retention — all-in-one

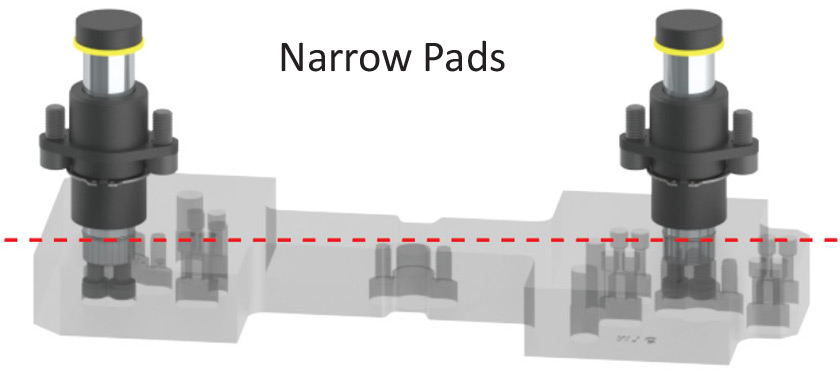

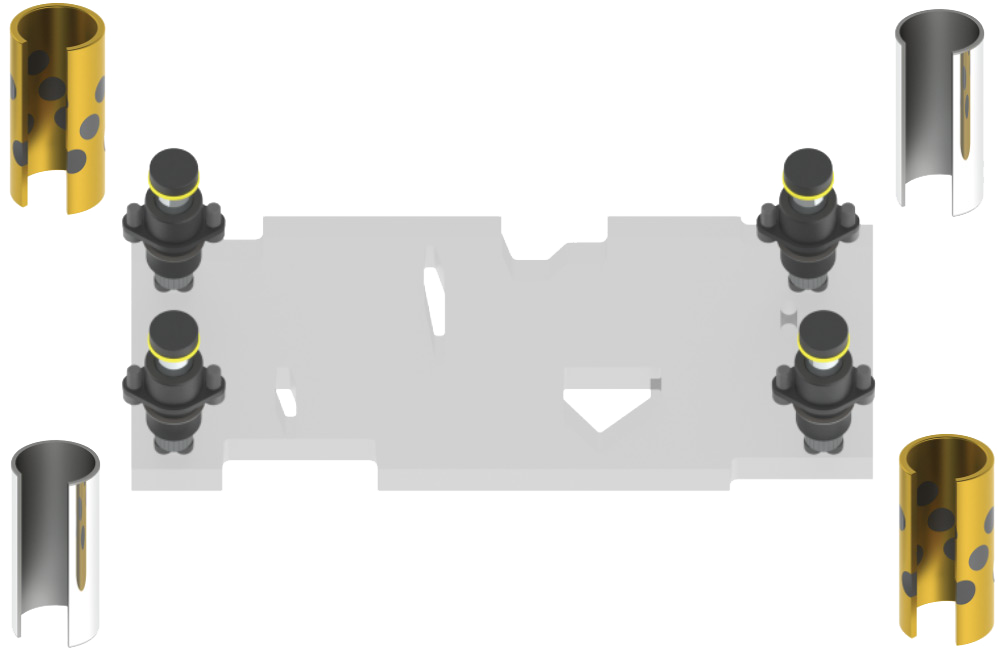

Trusted guidance and retention in an all-in-one assembly saves time and space in design, reduces material and overall pad size, and speeds up machining and die assembly.

Trusted guidance and retention in an all-in-one assembly saves time and space in design, reduces material and overall pad size, and speeds up machining and die assembly.

Superior performance

Commonality and savings in design and build

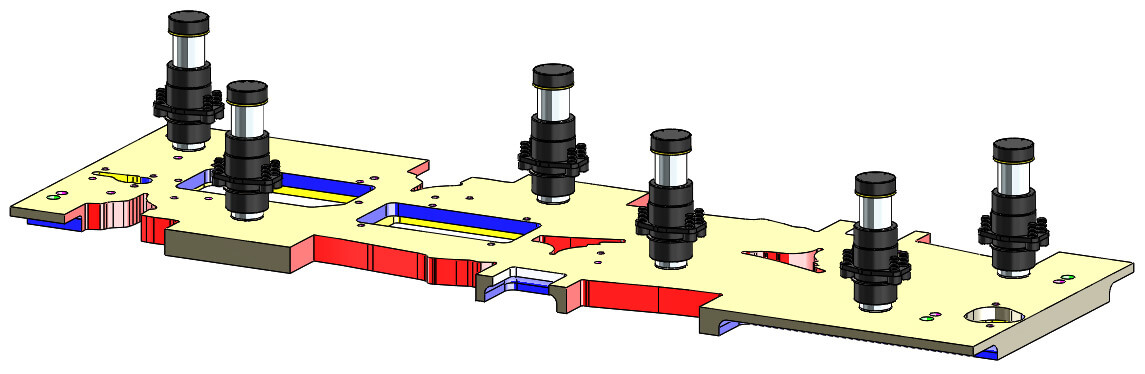

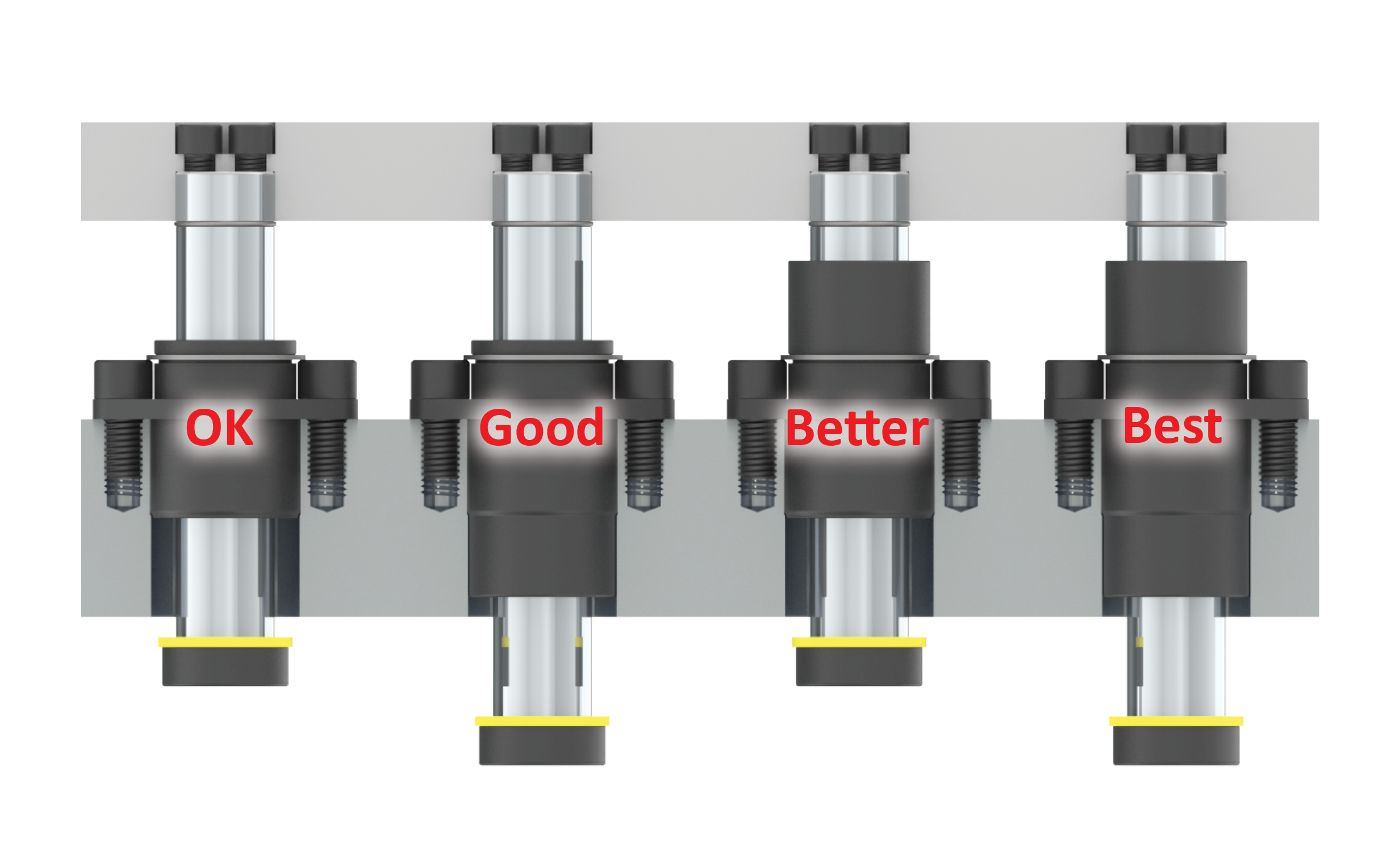

Our original Guided Keepers were designed for short-travel stripper pads. We recognized an opportunity to guide and keep all-in-one assembly, which reduced labor in design/machining and sped up die assembly.

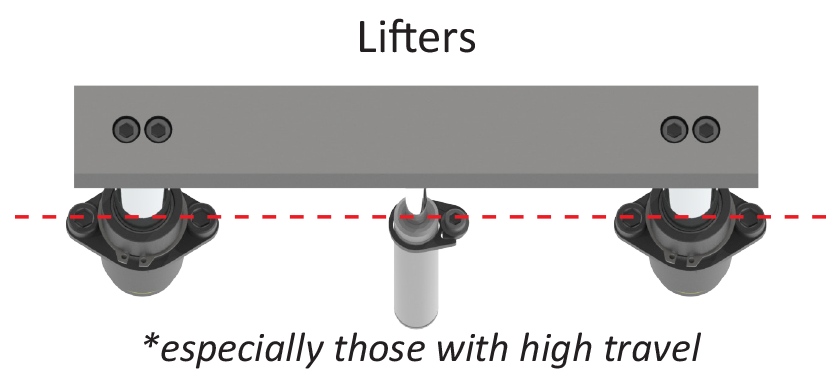

With the success and global adoption of our Guided Keepers, customers recognized their value in more than just short-travel stripper pads.

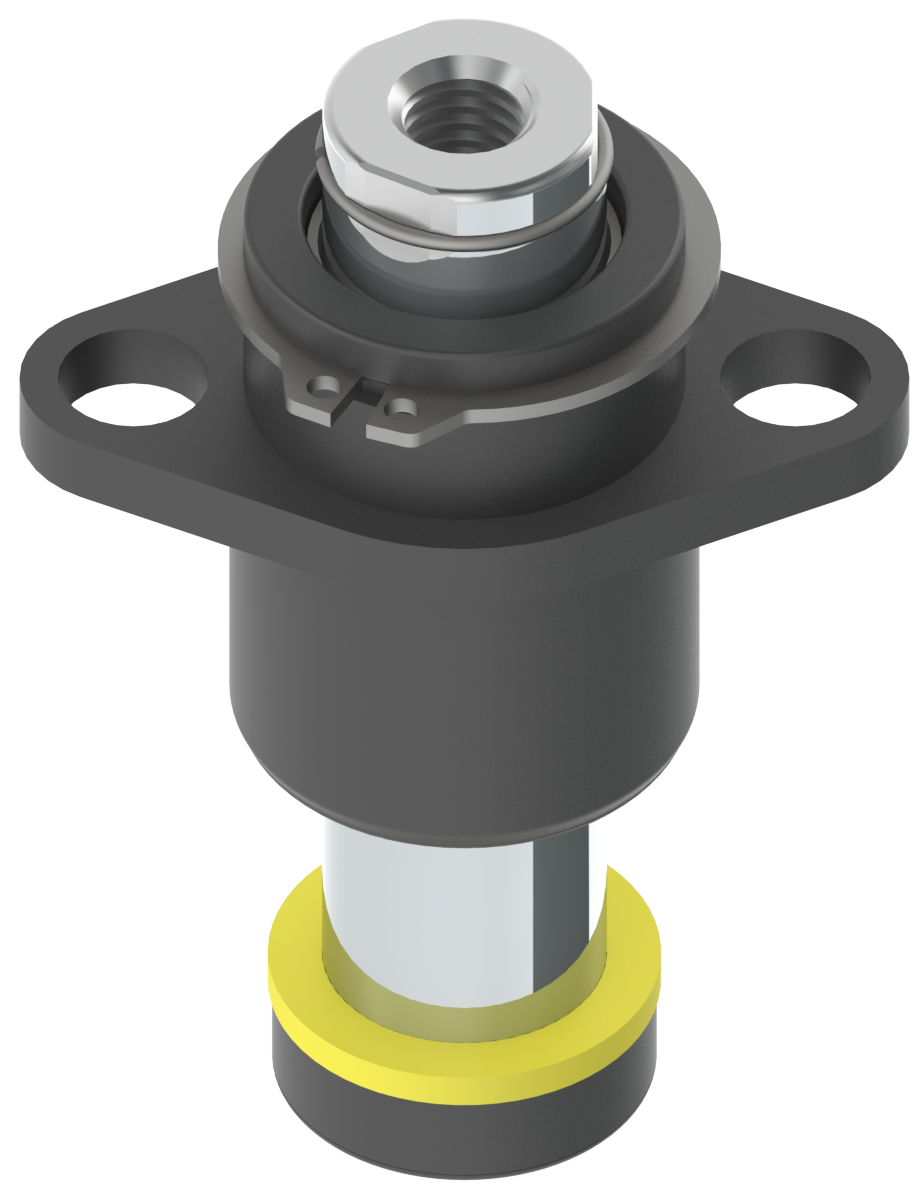

Our next design introduced longer and more cost-effective bore-located bushing styles. We also delivered new pin connection styles to increase robustness for high-demand applications.

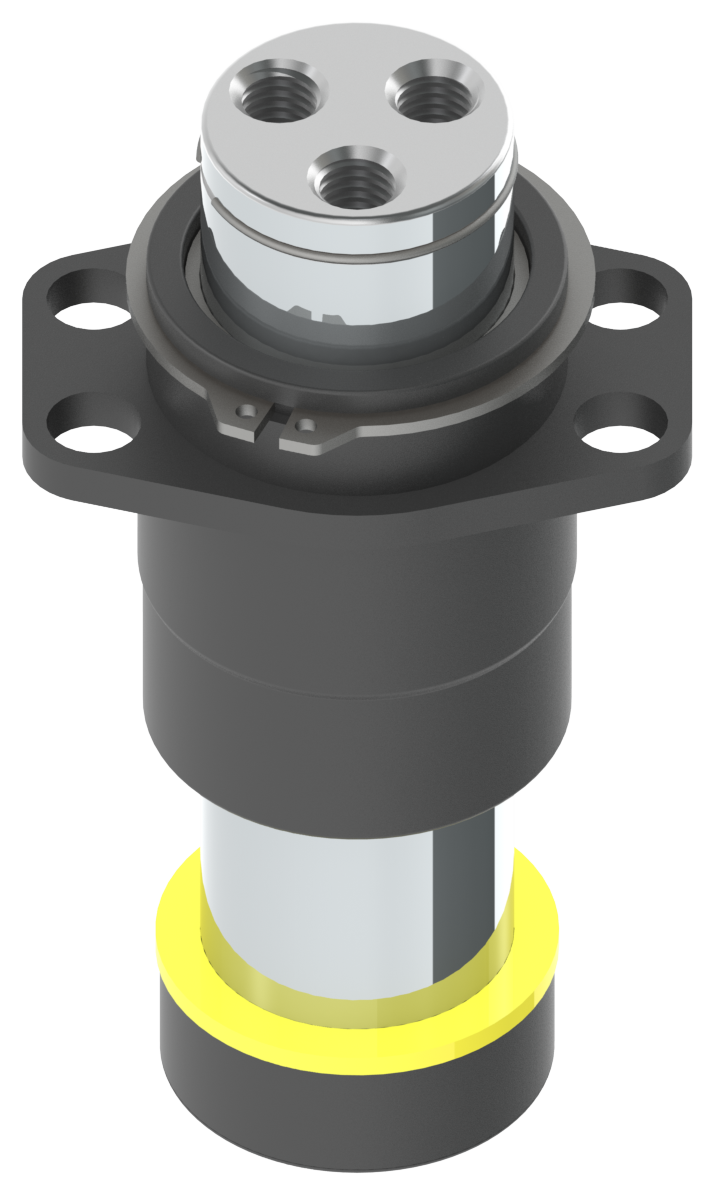

We continue to gain valuable insights from our global customer base and now introduce our newest generation of Guided Keepers. Continued innovation includes a new bushing option (bronze plugged) for high demand applications, new guide pin series for greater robustness, and our new “N” style, which allows for increased bushing configurations to maximize bushing length in your application.

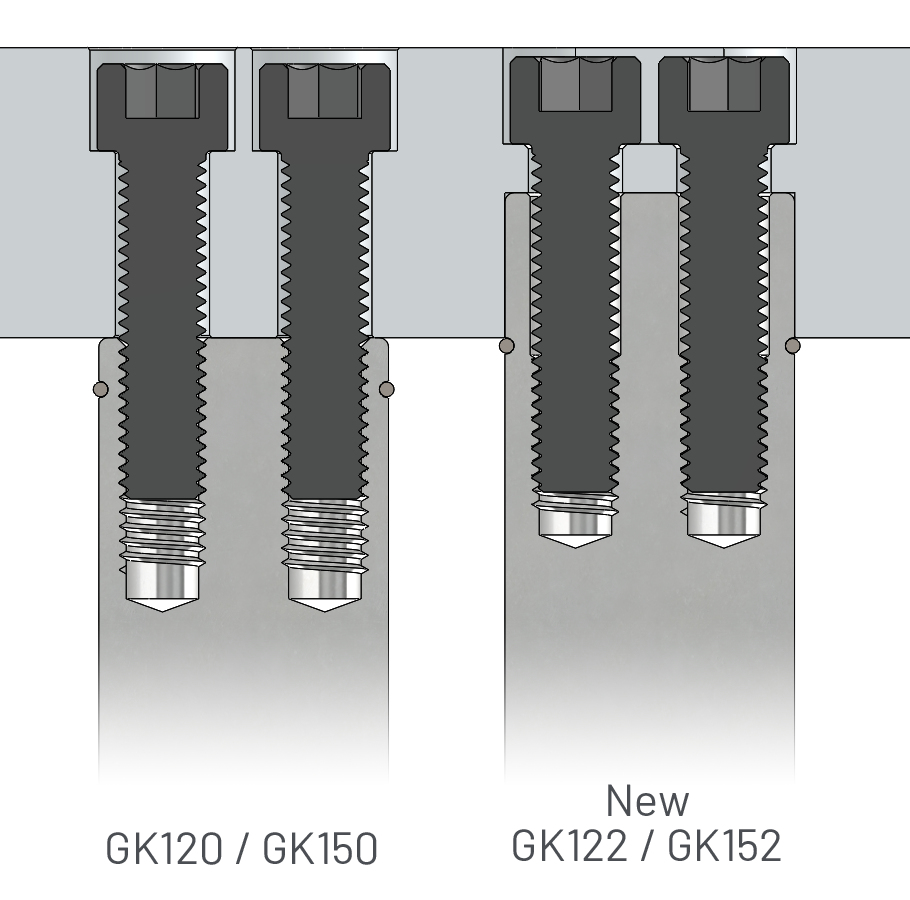

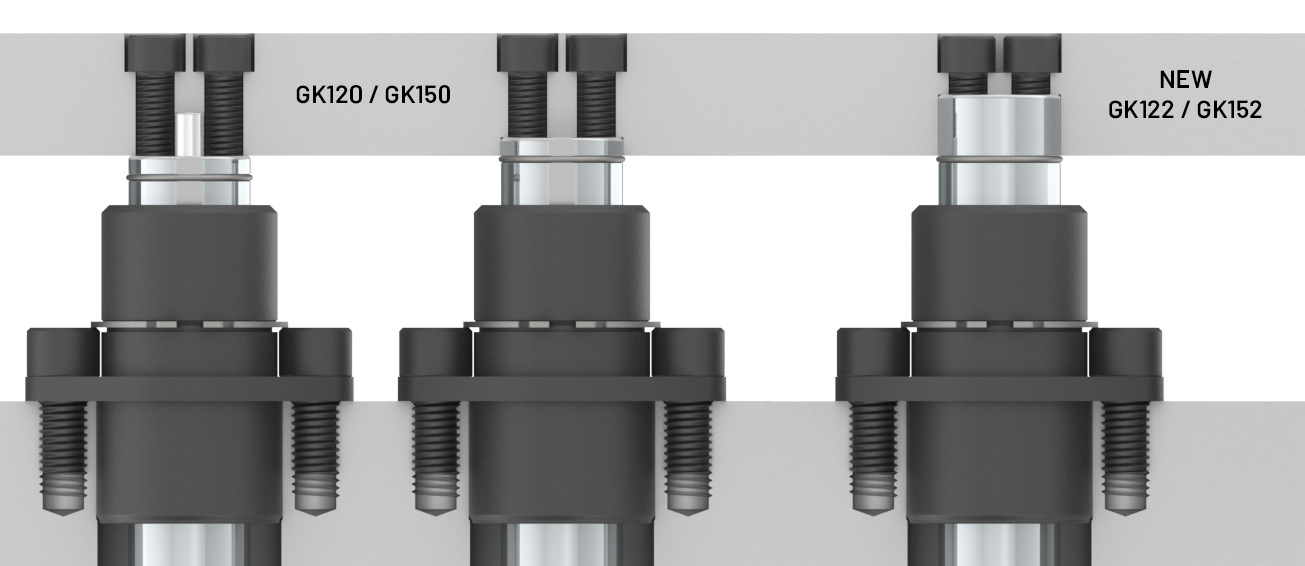

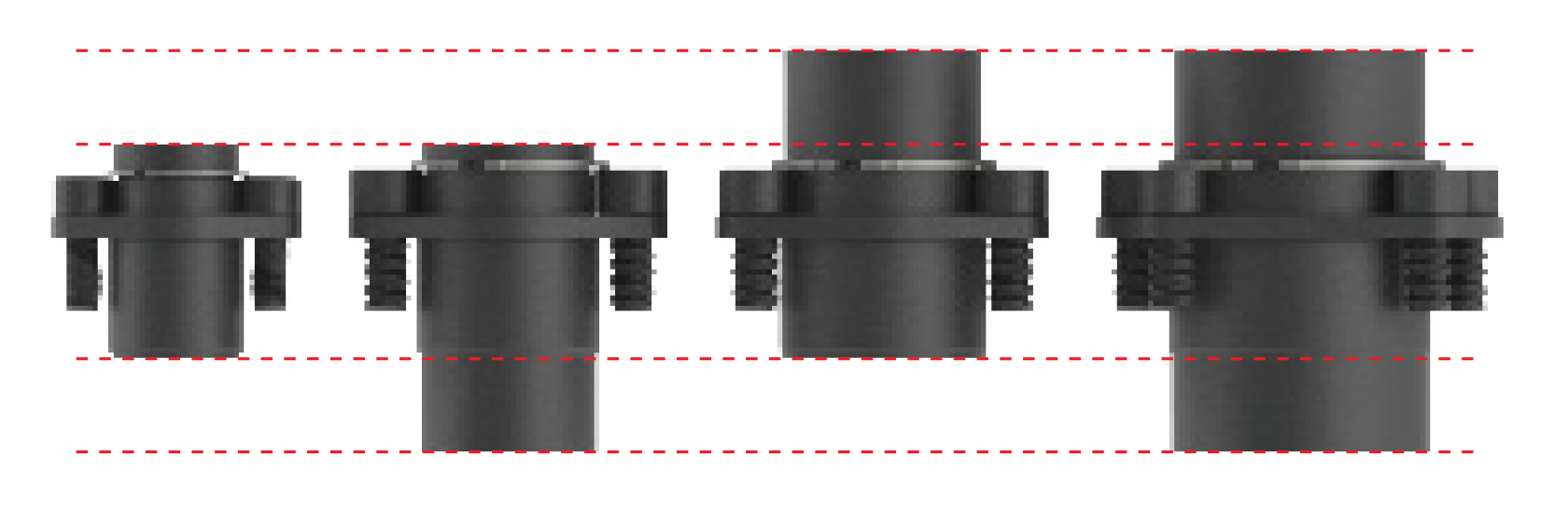

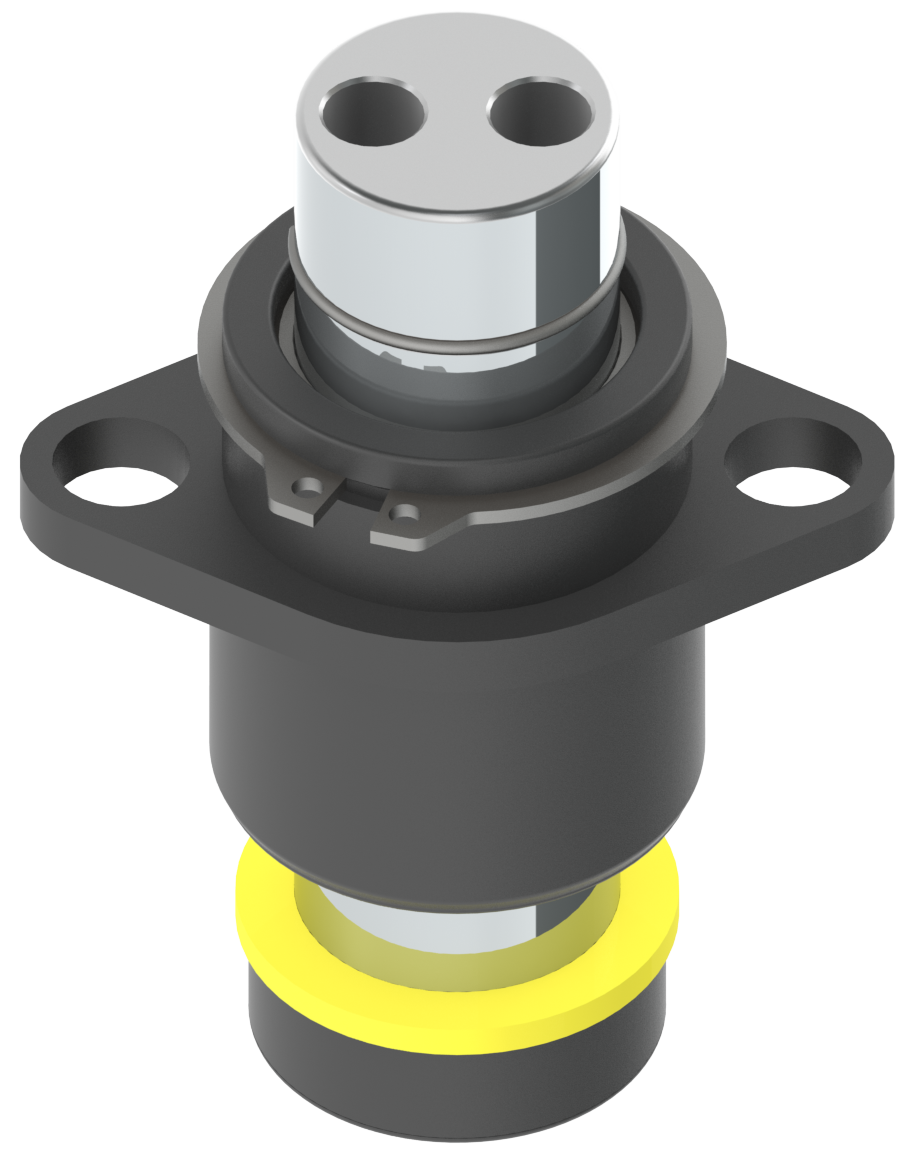

More robust connection to better protect fasteners in the event of a miss-hit or die crash.

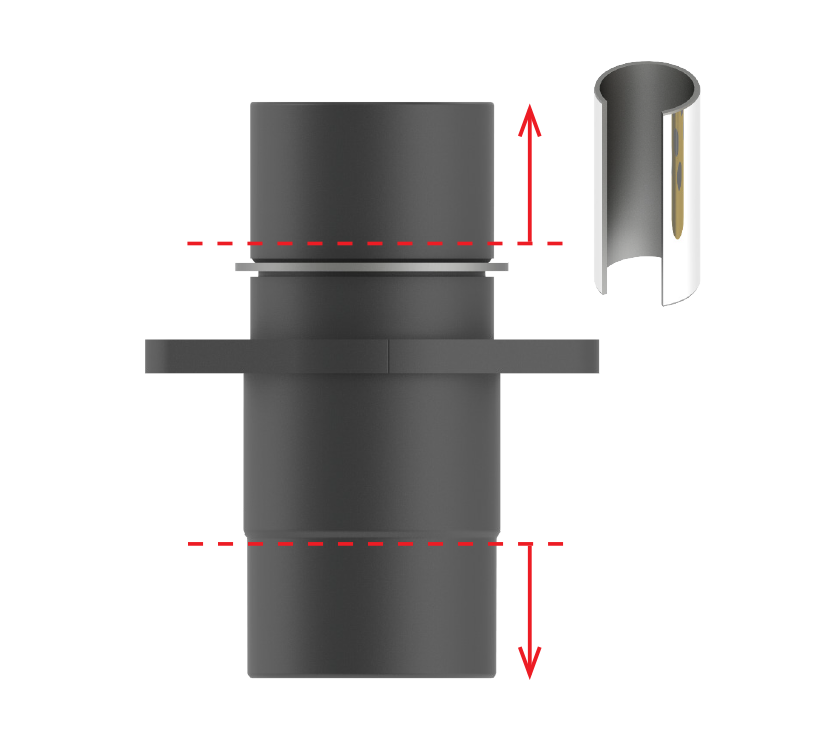

Improving upon the GK120 and GK150 guide pins, the new GK122 and GK152 are pocketed deeper and utilize long fasteners.

The guide pin is pocketed deeper

This provides more support for the guide pin if the pad or lifter rail tips. When a significant tip condition occurs the screws will start to stretch but the body of the guide pin will make contact with the sides of the pocket and it will limit the amount of stretch/force subjected on the fasteners.

During testing, it was identified that the depth of the pocket needs to be equal to at least 1/2 of the pin diameter for it to provide this type of support.

Note: Designed for a slip fit to allow for easier assembly, and to accommodate slight variation in machining tolerances of the die shoe and pad.

The threaded holes are deeper in the guide pin to still allow for long fasteners which provide more stretch/forgiveness in the event of a miss-hit or die crash.

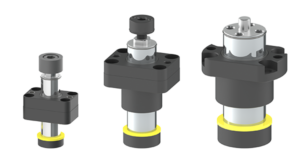

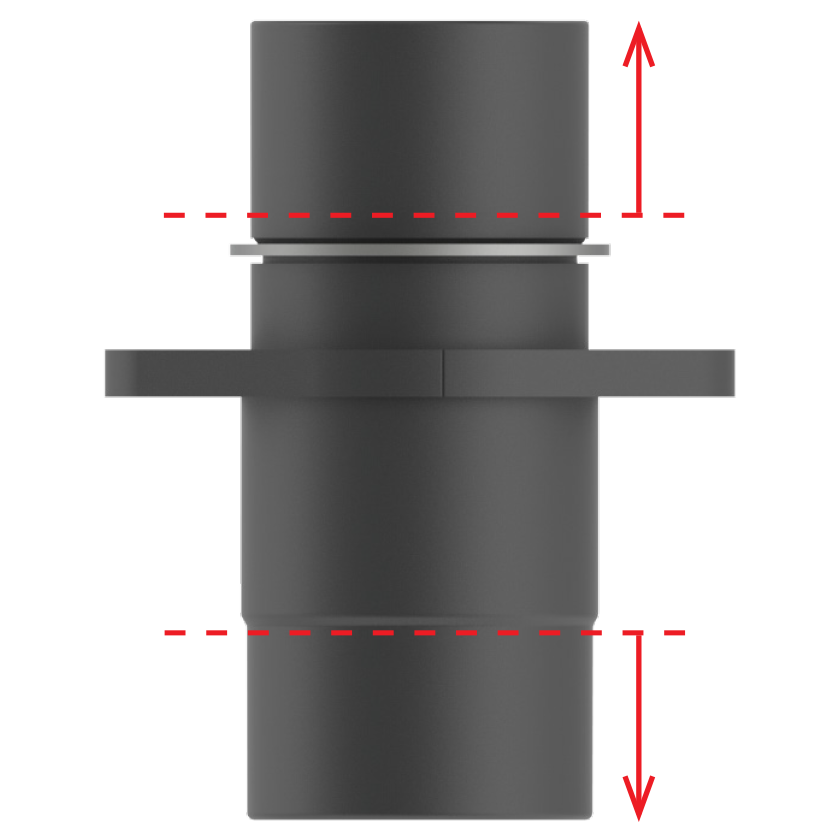

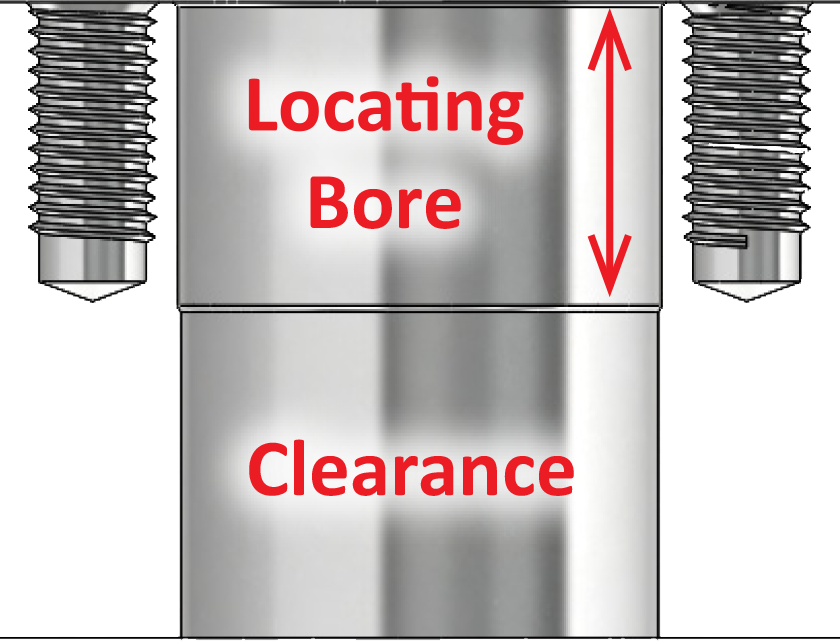

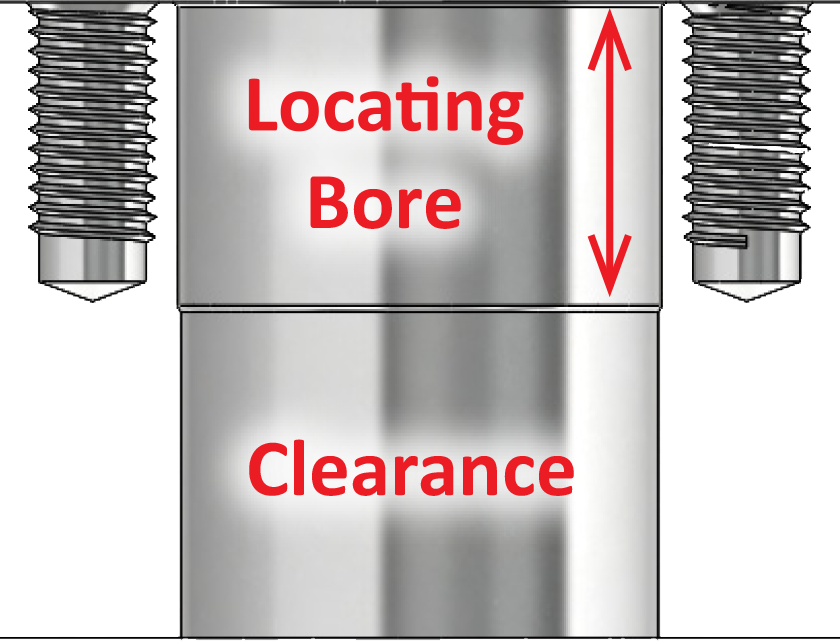

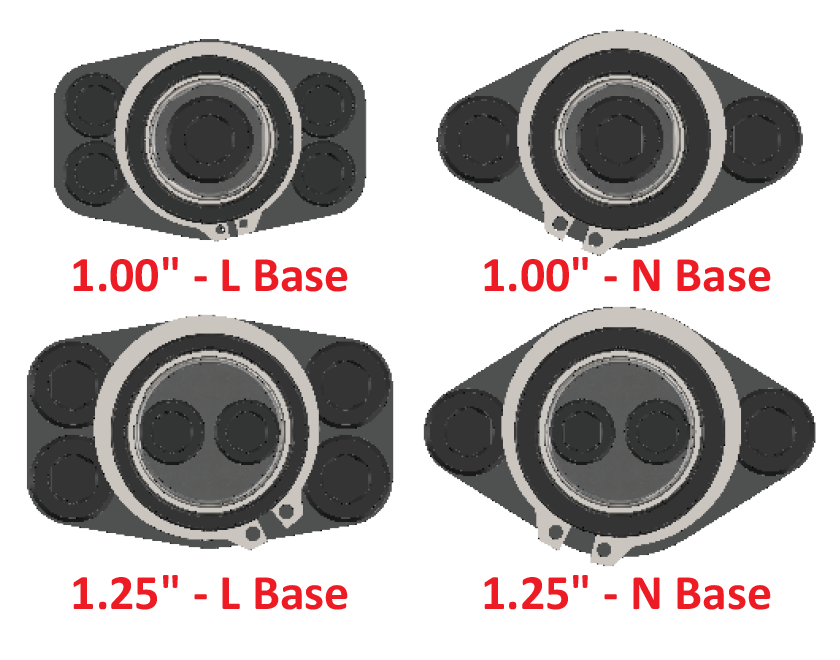

Allows for any free space above or below the base to be utilized to maximize bushing length which improves production performance.

Longer bushings provide significant value in production by improving the guidance condition along with extending the performance life of the assembly.

The new “N” style base provides more configuration options to maximize bushing length both above or below the base.

Taller “N” Base Options

This option adds 1.00” toward the back of the pad which utilizes the free space in this area to achieve a better die condition. Pro Tip: If the amount of space available is slightly less than what is needed to use the taller option the base may be mounted in a shallow pocket.

Longer “N” Base Options

Longer N bases are available in the following sizes:

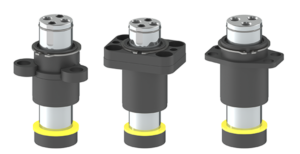

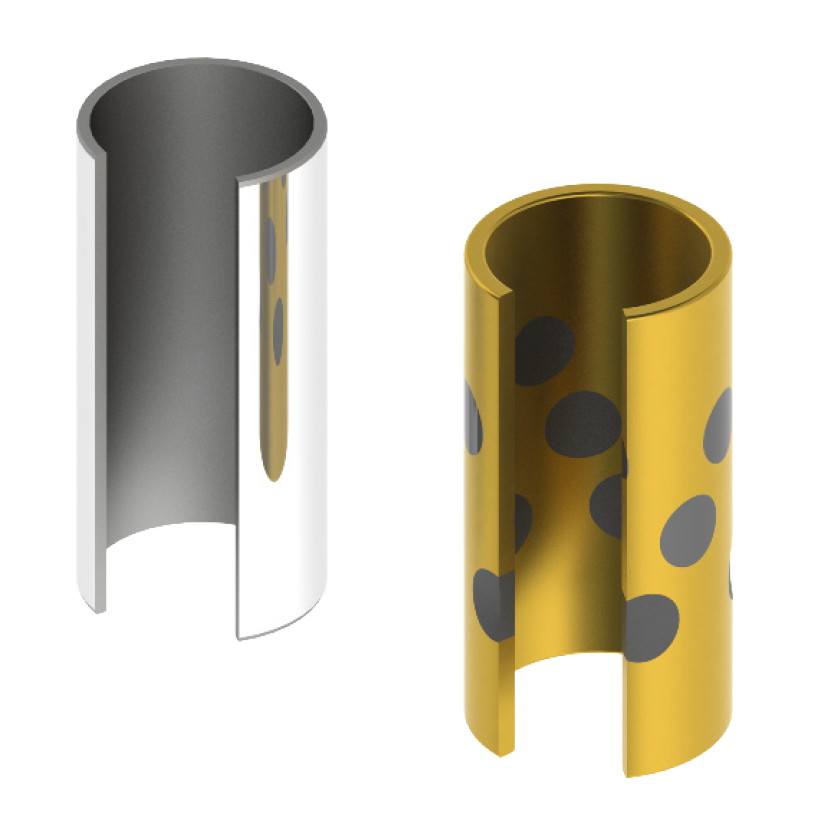

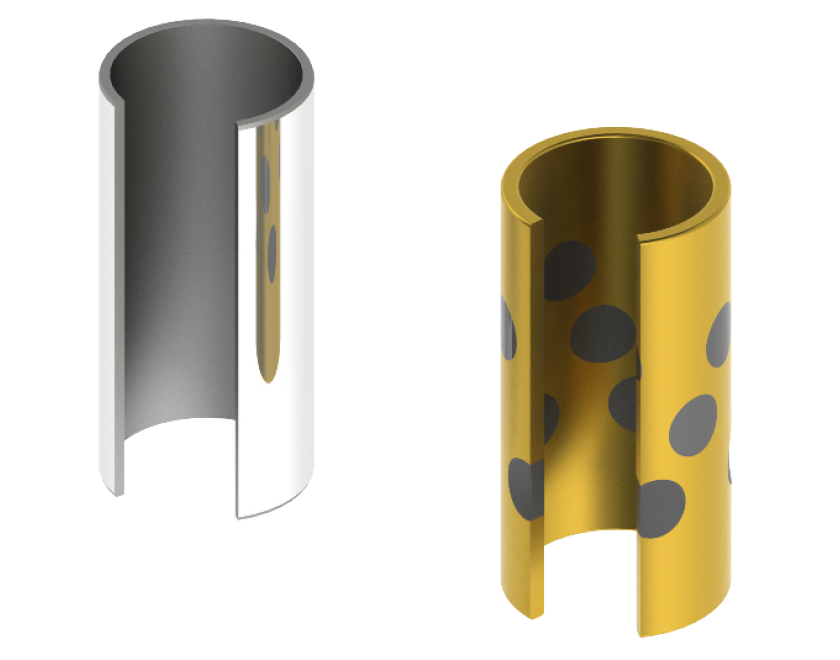

Bronze/Graphite Plugged option to support additional applications.

A New Bronze / Graphite Plugged Bushing option is now available. This new bushing option has advantages in high demand applications where the amount of movement in the pad or lifter needs to remain tighter longer.

When using more than two Bronze / Graphite Plugged bushings on single application you may experience a more challenging assembly. If more than two are required, we recommend using Bronze / Graphite Plugged bushings in opposite corners and using the standard(PTFE-Bronze) style bushings in all other locations.

Many of these “precision applications” may not need the Bronze / Graphite Plugged style bushing. In our experience, using longer bushing lengths with our more economical standard bushing style will achieve the desired precision needed for your application.

Easier machining — less taps required for some sizes and other features for increased robustness.

The base is designed to make the machining of the mounting bore easier, allowing for a short 1.25″ long endmill to be used. This makes it easier to machine to diameter and with a straight wall.

1.00″ and 1.25″ diameters are engineered so the connection strength of the base-to-shoe pairs appropriately with the connection strength of the guide pin-to-pad.

The same “N” base housing is used for both bushing types so if desired they may be easily changed in production without any machining required.

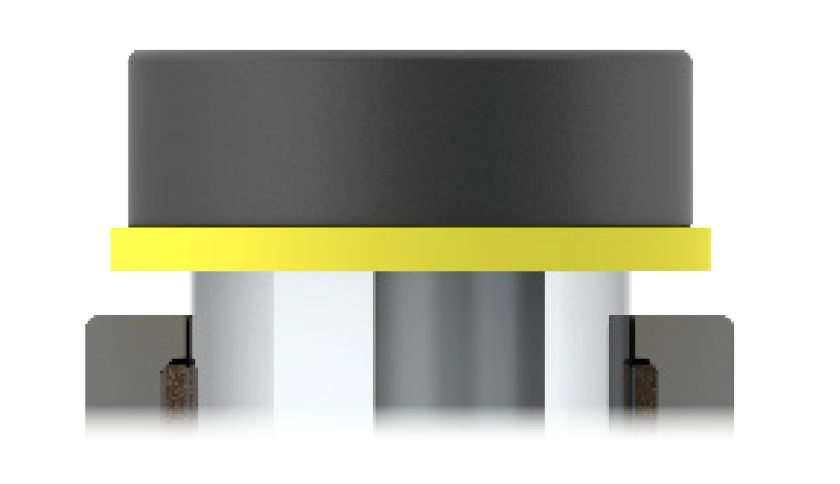

The dampening washer only contacts the steel base housing(not the bushing). This provides for a robust/flat surface for the Dampener to hit.

The dimensions from the mounting surface to the top/bottom of the bases are the same across all diameters.

$83.22

.75" Diam. / 2" Bushing

$97.80

1.00" Diam / 2" Bushing

$110.11

1.25" Diam / 2" Bushing

$131.11

1.50" Diam / 3" Bushing

$141.80

1.75" Diam / 3" Bushing

$184.25

2.00" Diam / 4" Bushing

Preview and download the CAD file you need with our product configuration tool.

See product configuration