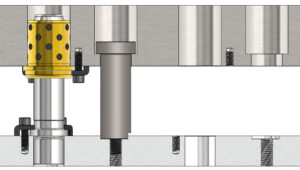

If you’re using the old-fashioned approach to guidance and retention, there’s a better alternative to the time-consuming and costly machining and assembly required by individual guide pins, bushing and spools/keepers.

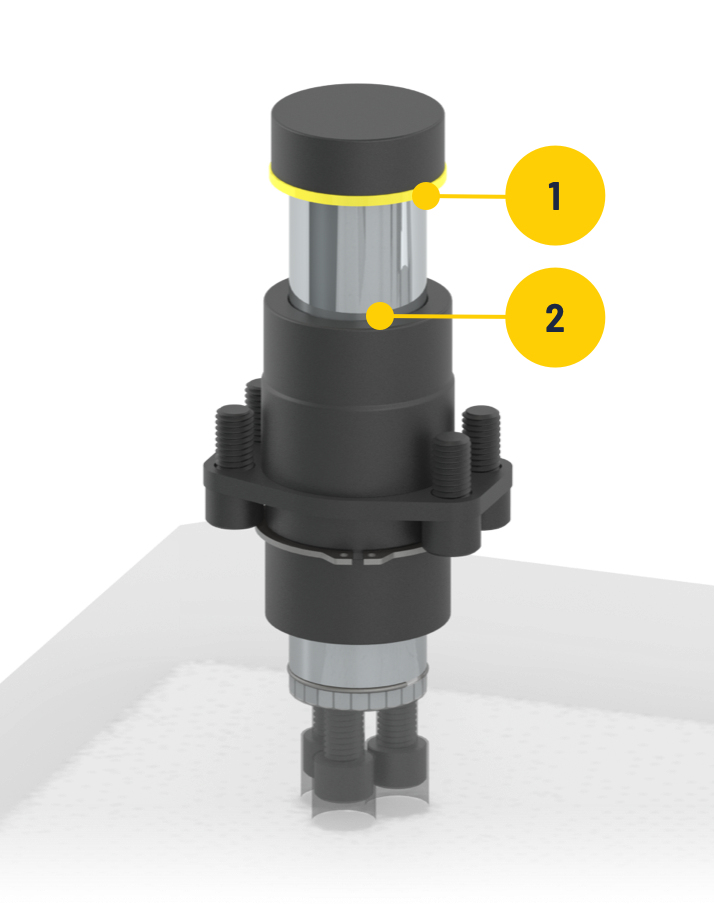

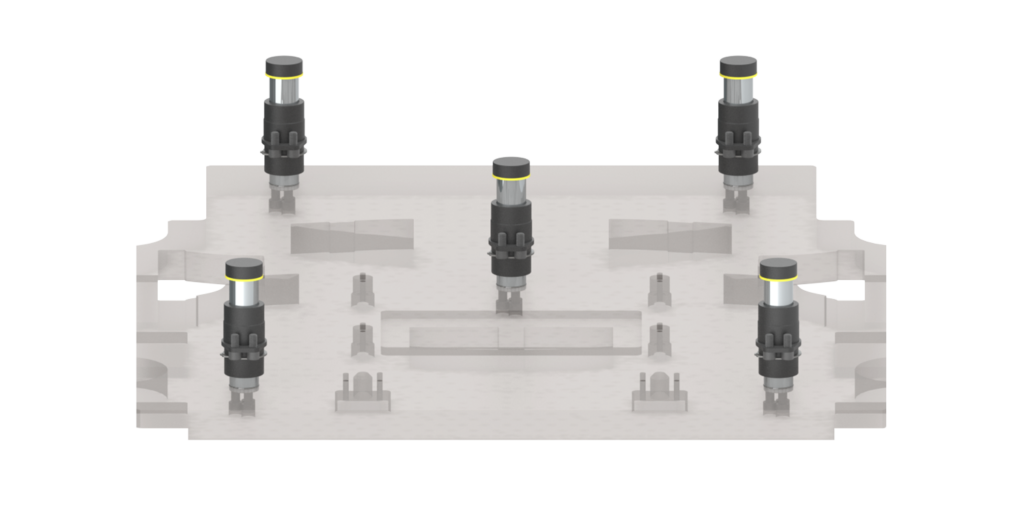

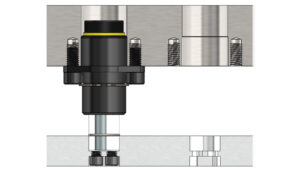

Our Guided Keepers put it all in a single robust assembly that’s far easier to design with and requires much less time and cost for machining and assembly. They also feature exceptionally high quality construction for greater operating precision and extended performance life.

- Retention

- Guidance