At Standard Lifters, we’re firm believers in creating and recommending more robust die components that increase the operating life and production accuracy of stamping dies.

By using the longest guided keeper bushing possible in available space, die designers and builders can significantly improve the guidance and performance of their dies and stamped part quality.

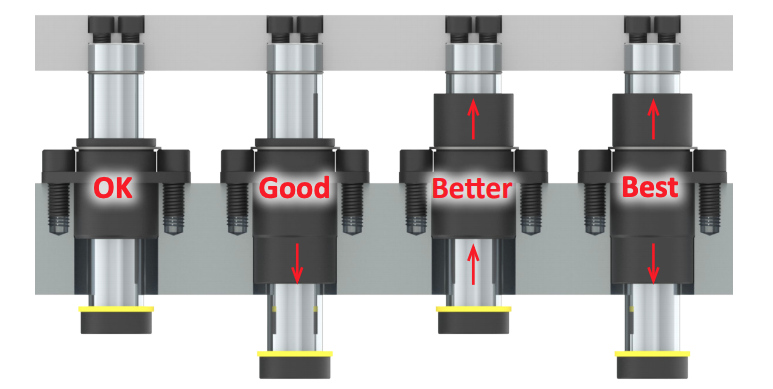

Longer Bushings vs Shorter Bushings

Guided Keepers with longer bushings can offer significant performance improvements over shorter bushings. Greater length provides increased guidance, reduced inaccuracies caused by wear, and improved performance life of the die.

We’ve analyzed replacement rates for guided keepers with a wide range of bushing lengths and have noted a 30% lower replacement rate when bushings are at least 1.6 times longer than their diameter. In short, longer bushings win!

Benefits of Longer Bushings in Dies

For die designers and die builders, the benefits of longer bushings appear in the design process and extend through the operating life of the die. The benefits of applying longer bushings in dies include:

- Improved guidance

- More efficient die space utilization

- Longer die uptime & extended working life

Improved Guidance

Longer bushings significantly improve surface contact area between the guide pin and the guide bushing. Fundamentally, this allows significantly less lateral movement of the guide pin as the die opens and closes. Stamping accuracy is improved, guide pin and bushing wear are reduced, and the performance life of the die is increased.

More Efficient Die Space Utilization

Longer bushings give die designers a very space-efficient and flexible approach to increasing robustness and accuracy. Our “N” style Guided Keeper base provides the most configuration options to maximize bushing length. The “tall” option on the “N” base adds 1.00″ toward the back of the pad to achieve greater precision and reduced wear.

Longer Die Uptime & Extended Working Life

With more surface area and greater operating precision, Guided Keepers with longer bushings last longer and improve die uptime. Choosing this more robust solution means you can focus on running parts.

Long bushings make good sense all the way around. and by reducing wear, they extend the working life of the die and reduce component replacement rates.

Interested in learning more about improving your die performance and life with longer bushings?

Visit our Guided Keepers Technical Data page OR start with our technical sheet on bushing length.

Have questions? We’re always available. Contact Standard Lifters to learn more about our Guided Keeper line.