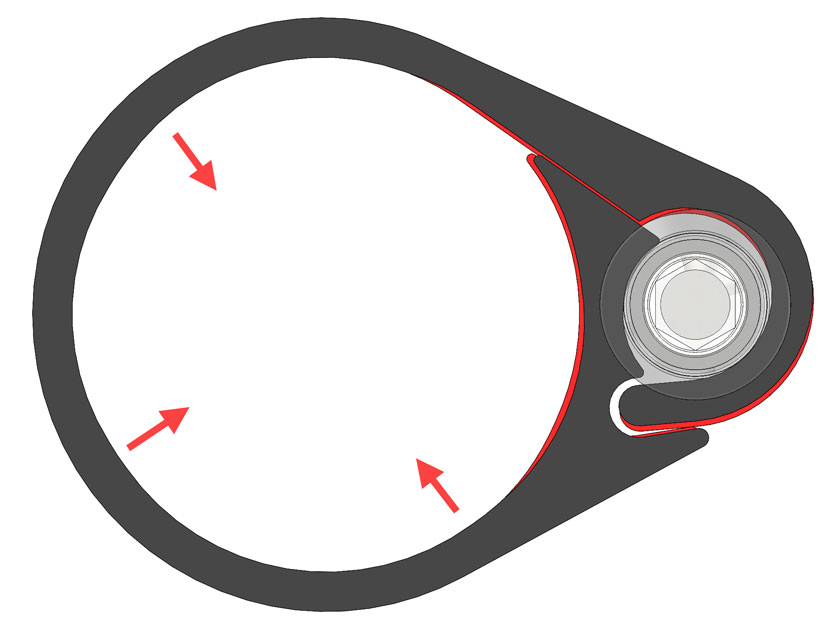

Circumferential clamping

The clamp makes contact in multiple locations, providing robust holding strength while centering the gas spring.

The clamp makes contact in multiple locations, providing robust holding strength while centering the gas spring.

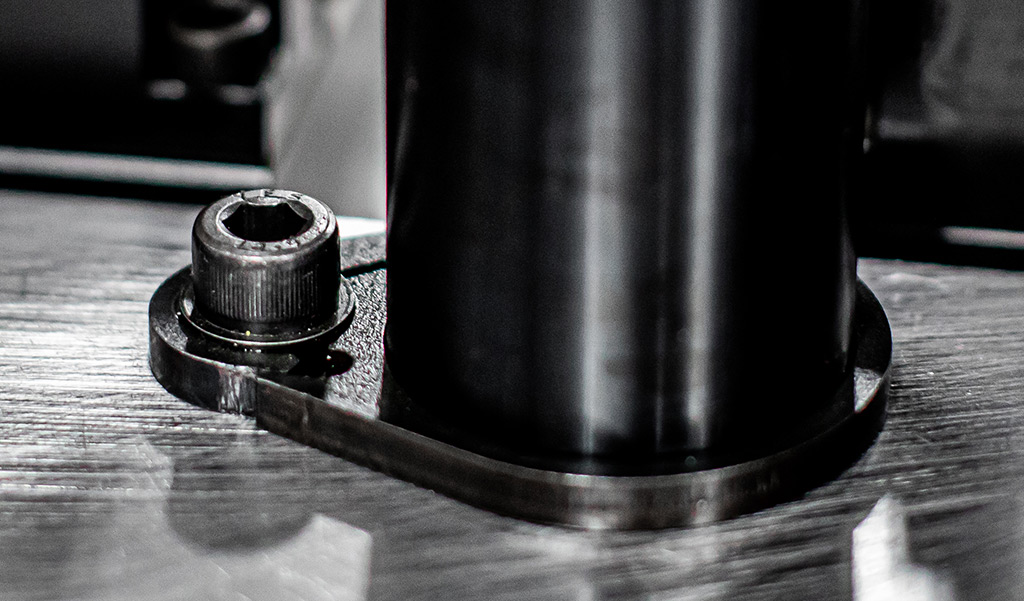

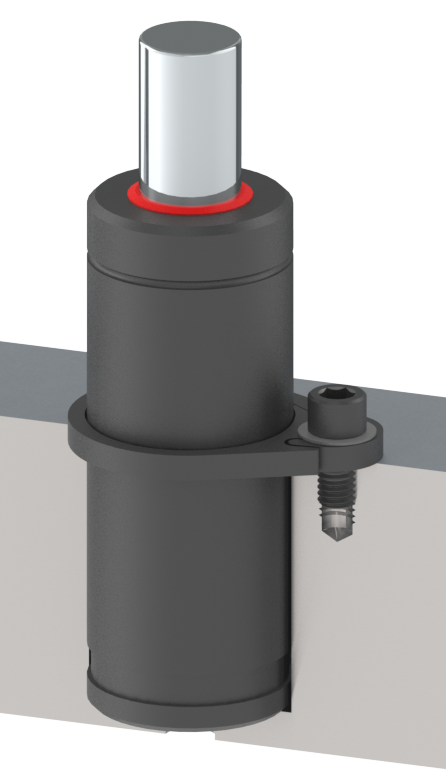

The clamp features single-tap machining and is compatible with all other clamp spring brands.

Standard Lifters’ Gas Spring Clamps are the easy choice when it comes to the innovative body containment, the simplified machining (taps only), and the unclamping for cylinder maintenance.

SL clamps offer our tooling a simple yet mechanical clamping solution that can be easily accessed in-press. They work great, and we require them in all our builds.

Starting at $6.50

GSC-25-B-E/M

Starting at $8.00

GSC-38-B-E/M

Starting at $9.00

GSC-50-B-E/M

Starting at $10.00

GSC-63-B-E/M

Preview and download the CAD file you need with our product configuration tool.

See product configuration